OUR FLEET

EdS Infrastrutture has implemented its own fleet of vehicles and special equipment - even exclusively designed and built - in order to be able to carry out each job quickly and efficiently.

Technologically advanced solutions and specific qualifications for operators allow rapid achievement of the set objectives

The company has also activated cutting-edge control processes in order to guarantee the maintenance and periodic renewal of vehicles and equipment with certainty and timeliness.

EdS Infrastrutture continuously invests resources for the strengthening and modernization of the park, purchasing both standard and new concept vehicles; keeping pace with technological evolution in compliance with the highest safety, quality and environmental standards.

- ROAD VEHICLES

- RAILWAY VEHICLES

- TOOLS

- MULTIPLE DRILLING MACHINE

NO NOISE TO THE HUMAN EAR!

Made exclusively on commission by EdS Infrastrutture, this machine allows the simultaneous execution of 4 or 6 holes on the face of the tunnel or reinforced concrete structures.

The articulated and telescopic arm allows you to reach heights of over 10 metres.

For drilling on reinforced concrete tunnel faces with 4 core drills, the time required for positioning and drilling is approximately 15 minutes.

The possibility of positioning the platform on different vehicles allows its use in every phase of processing inside the tunnels, with or without tracks.

All components offer maximum reliability and the design was created taking into account all drilling needs in every position.

- MULTIPLE DRILLING MACHINE

NO NOISE TO THE HUMAN EAR!

Made exclusively on commission by EdS Infrastrutture, this machine allows the simultaneous execution of 4 or 6 holes on the face of the tunnel or reinforced concrete structures.

The articulated and telescopic arm allows you to reach heights of over 10 metres.

For drilling on reinforced concrete tunnel faces with 4 core drills, the time required for positioning and drilling is approximately 15 minutes.

The possibility of positioning the platform on different vehicles allows its use in every phase of processing inside the tunnels, with or without tracks.

All components offer maximum reliability and the design was created taking into account all drilling needs in every position.

- MULTIPLE DRILLING MACHINE

NO NOISE TO THE HUMAN EAR!

Made exclusively on commission by EdS Infrastrutture, this machine allows the simultaneous execution of 4 or 6 holes on the face of the tunnel or reinforced concrete structures.

The articulated and telescopic arm allows you to reach heights of over 10 metres.

For drilling on reinforced concrete tunnel faces with 4 core drills, the time required for positioning and drilling is approximately 15 minutes.

The possibility of positioning the platform on different vehicles allows its use in every phase of processing inside the tunnels, with or without tracks.

All components offer maximum reliability and the design was created taking into account all drilling needs in every position.

- MULTIPLE DRILLING MACHINE

NO NOISE TO THE HUMAN EAR!

Made exclusively on commission by EdS Infrastrutture, this machine allows the simultaneous execution of 4 or 6 holes on the face of the tunnel or reinforced concrete structures.

The articulated and telescopic arm allows you to reach heights of over 10 metres.

For drilling on reinforced concrete tunnel faces with 4 core drills, the time required for positioning and drilling is approximately 15 minutes.

The possibility of positioning the platform on different vehicles allows its use in every phase of processing inside the tunnels, with or without tracks.

All components offer maximum reliability and the design was created taking into account all drilling needs in every position.

- MULTIPLE DRILLING MACHINE

NO NOISE TO THE HUMAN EAR!

Made exclusively on commission by EdS Infrastrutture, this machine allows the simultaneous execution of 4 or 6 holes on the face of the tunnel or reinforced concrete structures.

The articulated and telescopic arm allows you to reach heights of over 10 metres.

For drilling on reinforced concrete tunnel faces with 4 core drills, the time required for positioning and drilling is approximately 15 minutes.

The possibility of positioning the platform on different vehicles allows its use in every phase of processing inside the tunnels, with or without tracks.

All components offer maximum reliability and the design was created taking into account all drilling needs in every position.

- CRANE WITH WINCH

EdS Infrastrutture has several cranes, both on rubber and on railway carriages, to be able to carry out any type of work such as construction, overhaul and maintenance of systems in general.

One of the characteristics of the machine is that it is designed and constructed so that it can be easily transported both by road and by rail, all with just a few simple set-up operations. There are many devices on the machine that provide operational safety and functionality, such as the parking system with "TRISTOP" type spring cylinders, a runway lighting system, a powerful lighting system for night work.

In particular, some vehicles built to EdS Infrastrutture specifications - with particularly long arms and equipped with various accessories - allow the rapid and precise installation of sheet piles and road, motorway and railway acoustic barriers.

CARRO BETONAGGIO

EdS Infrastrutture has railway batching wagons of adequate dimensions for quick and easy interventions for the creation of variations, doublings, short sections, etc...

The system works with self-produced energy from endothermic engines and electric accumulators. It allows the loading, containment, mixing and unloading of the materials needed for the production of concrete.

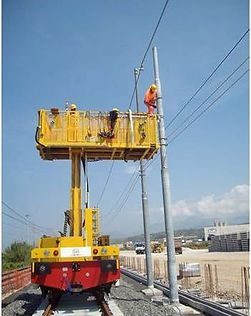

- DEVELOPABLE BRIDGES

EdS Infrastrutture has equipped its fleet with various "Motorized ladders" intended for personnel working on electric traction systems, for the construction, overhaul and maintenance of overhead electric traction lines. Belonging to category "G" of the new railway regulations, it has been designed to facilitate interventions on electric traction equipment, located at very high altitudes compared to the railway level, considerably increasing operations, in compliance with safety and protection of the health of the personnel who work there.

The main innovations adopted consist of the implementation of a "TRANSPORT SETUP" without the use of special vehicles, both on road and by rail, and of operation without the use of ground stabilizers.

- DEVELOPABLE BRIDGES

EdS Infrastrutture has railway batching wagons of adequate dimensions for quick and easy interventions for the creation of variations, doublings, short sections, etc...

The system works with self-produced energy from endothermic engines and electric accumulators. It allows the loading, containment, mixing and unloading of the materials needed for the production of concrete.

- DEVELOPABLE BRIDGES

EdS Infrastrutture has railway batching wagons of adequate dimensions for quick and easy interventions for the creation of variations, doublings, short sections, etc...

The system works with self-produced energy from endothermic engines and electric accumulators. It allows the loading, containment, mixing and unloading of the materials needed for the production of concrete.

- DEVELOPABLE BRIDGES

EdS Infrastrutture has railway batching wagons of adequate dimensions for quick and easy interventions for the creation of variations, doublings, short sections, etc...

The system works with self-produced energy from endothermic engines and electric accumulators. It allows the loading, containment, mixing and unloading of the materials needed for the production of concrete.